After having exhaustively addressed the issue of Six Sigma in my previous articles I will now give some explanations on Lean Six Sigma:)!

Lean Six Sigma is a method that combines the approaches of Lean Management and Six Sigma. Using this method will help increase customer satisfaction, increase quality, and will also save costs. In this context, monetary effects result from avoiding waste or reducing the amount of it (e.g., by reducing delivery times or stocks).

In a first step applying Lean Management methods will decrease the complexity of your processes and accelerate them, in a second step using Six Sigma will have the effect of ensuring and increasing quality.

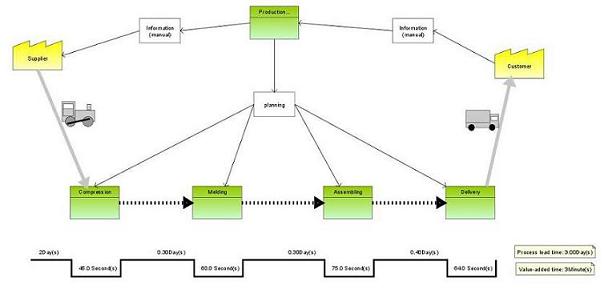

A well-established method in the Lean Six Sigma environment is value stream mapping. This method visually maps the current flow of materials and information (define phase). It combines all activities and processes required for transforming raw materials into the finished product and for delivering the product to the customer. The following graphic illustrates a value stream map in ARIS Six Sigma.

The value stream mapping method serves to identify potential waste. There are 7 sources of waste:

- Overproduction

- Wait times

- Transport

- Overprocessing

- Inventory

- Inspection/Rework

- Motion

The value stream offers various options for analysis, such as calculating cycle times. ARIS Six Sigma provides a number of reports and macros for evaluation purposes. For example, the 'Timeline' macro calculates cycle times and draws a line that visualizes these times below the model.

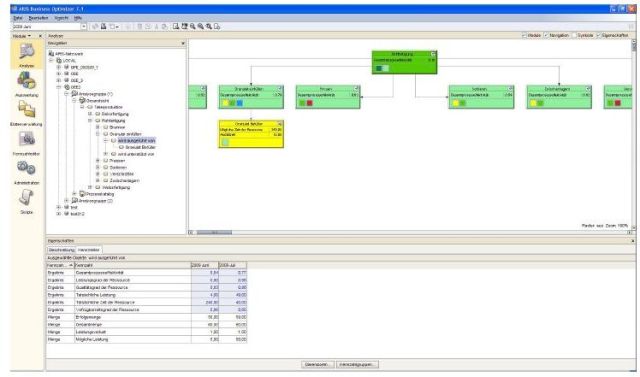

The 'Collect overall process effectiveness data' report provides an Excel sheet where you can specify different values that are relevant for calculating the overall process effectiveness for each process in the value stream. Once this sheet is filled with data you can import it via the 'Import overall process effectiveness data' report. Based on the Excel sheet data the report calculates the performance, quality, and availability rates, as well as the overall process effectiveness.

To enable a more detailed calculation of the overall process effectiveness, ARIS Six Sigma offers a rule set for ARIS Business Optimizer.

Performing a value stream analysis is also possible by means of the 'Kaizen process mapping' report. You can use this report in order to analyse which process steps in the EPCs assigned to the value stream process steps are value-added and which are not.

Another report identifies the actual processing time and compares it with the cycle time. This report calculates individual process steps and provides a bar chart for displaying the comparison results.

The Lean Six Sigma method thus enables companies to combine the concepts of Lean Management and Six Sigma in a way that guarantees a lasting increase in quality and ensures that the company will stay competitive in the long run.

Katrina Simon on

Thank you very much Eva for this great introduction. I am currently preparing a value stream mapping workshop at a customer's site. We will be actually walking the shop floor and gathering data for VSM-models which will be documented in ARIS afterwards.

Please stay tuned for my upcoming post on the details of VSM-modelling.