I am attending ARIS ProcessDay in Singapore. Right now Evelyn Stier is talking about Business Process Management Governance at Siemens. A big organization such as Siemens has to be flexible, but at the same time needs to ensure that governance processes are implemented. In 2001, Siemens started a process standardization program. One central framework was created to describe the processes in the company. If you take into account that at Siemens more than 400,000 people are employed you can imagine the complexity of the project.

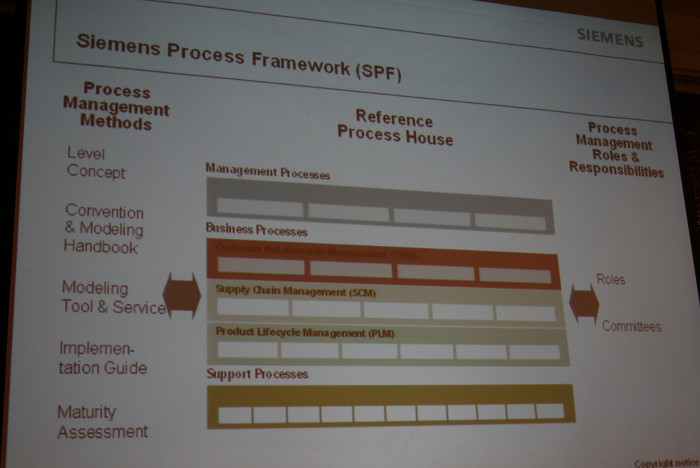

The Siemens Process Framework consists of 3 pillars. The people from the different units had different views on the processes. So it took a while to get everybody on the same page. But this was essential for the success of the process. They agreed on a common set of conventions and on a common tool which is – take a wild guess – ARIS! Another important part is the announcement of Process Owner roles although the organization. Siemens has 7000 processes modeled and optimized. All business units are using the same set of standardized processes.

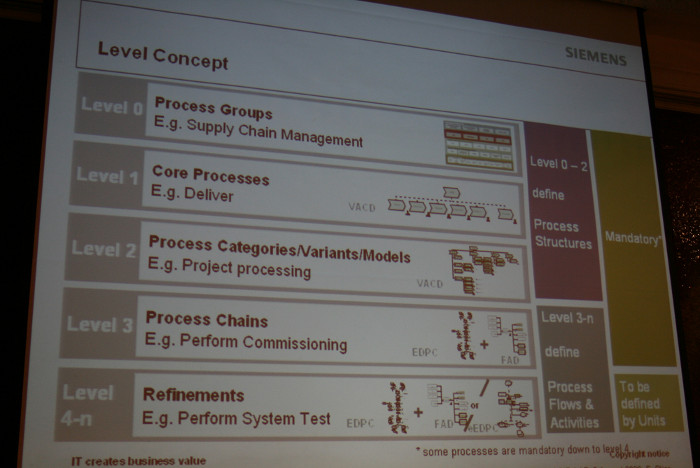

In the Level concept on the next picture, you see the process hierarchy of Siemens. Level 0 to level 3 are mandatory. Level 4 can be decided by the business units. By doing this, Siemens is maintaining flexibility. Another interesting part of the presentation includes the role and responsibility structure of the project.

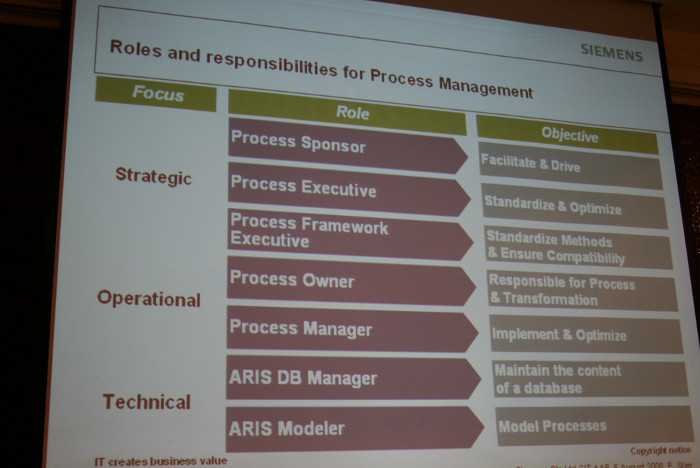

The hierarchy is broken down to strategic goals and operational roles. The technical roles are assigned to the technical setup of ARIS in the project.

The strategic roles are very important. Unfortunately, in some projects in other companies they were not created and so the projects failed. Business Process Management is not about technology. Its about a process-driven organization. Process thinking has to be established. This doesn’t work if you just focus on the setup of a modeling software or operational management. This approach has to be reflected also on the management level. Objectives and KPIs have to be mapped to processes. People have to establish a responsibility for THEIR very process because - Your process needs YOU ;-)

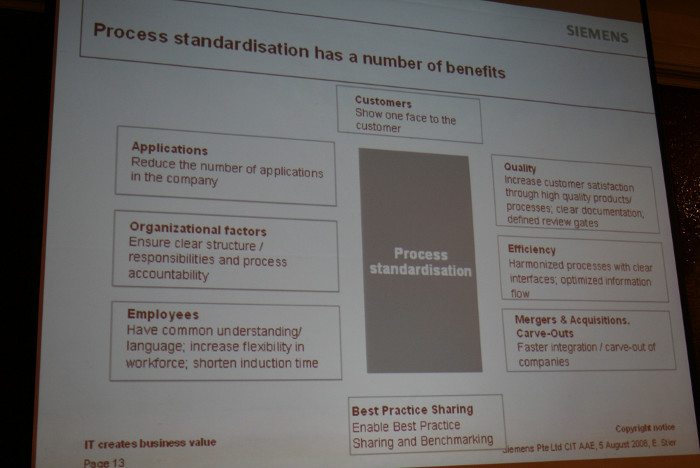

Siemens is also using ARIS Process Performance Manager. With this tool they ensure that the executed processed really reflect the processes designed in ARIS. Based on the process data extracted from different IT systems, they continuously improve their processes. What benefits did Siemens generate by standardizing their processes? Well, I would say quite many. See for yourself:

My presentations on Innovations and Process Intelligence are about to come up. I better prepare quickly. Gotta run…